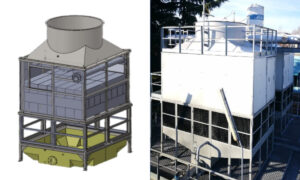

TRC series by SCAM T.P.E offers open circuit cooling towers with lateral forced centrifugal ventilation, with a wide range of thermal potentials from hundreds of kW to very respectable sizes up to 2 MW. All models apply a modular concept. They are usually used in low-noise residential air conditioning, but are also successfully used in “light” industrial refrigeration.

The main features of these oper circuit evaporative towers are the following ones:

STRUCTURE / MONOLITHIC ENCLOSURE (body, fan stack and collection basin).

Built in galvanized plate with a minimum thickness of 20/10. All panels are bonded to give strength to the unit and assembled with galvanized bolts. A special silicone mastic, which permanently retains elasticity, ensures watertight integrity between the panels. A special waterproof material is applied inside the water collection basin, to guarantee its tightness. The basin is complete with all the connections necessary for proper functioning. A by-pass between the water inlet and the “overflow” allows the continuous discharge of a part of the water returning from the utility, thus ensuring the control of the concentration of salts dissolved in the circuit. The corrosion protection of carpentry is ensured by an external epoxy paint and internal bituminous one.

BOLTS are supplied as standard on this model in galvanized carbon STEEL. Upon request, it is possible to propose stainless steel as construction material for the tower, where the characteristics of the project make it essential to use noble metallurgy, highly resistant to corrosion.

VENTILATION UNIT

The ventilation unit, with indirect transmission in the lower area of the tower, consists of:

– one or more SCAMAIR / SC centrifugal fans with single or double aeraulic intake, made of galvanized plate with impeller keyed onto a cadmium-plated steel shaft, supported by ball bearings, coupled to the electric motor with belt transmission and trapezoidal pulleys.

– SCAM T.P.E. electric motor three-phase multi-voltage (230/400 – 400/690) and multi-frequency (50-60 Hertz) specific for cooling towers with external ventilation, mounted on belt tensioner slides inside the fan section equipped with a galvanized steel fan protection grid.

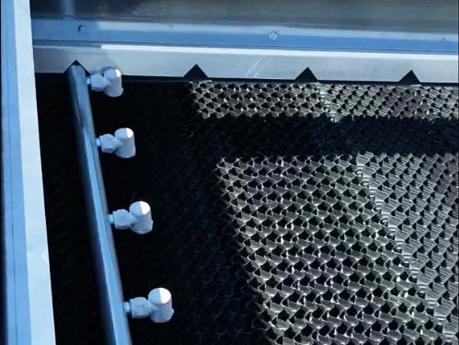

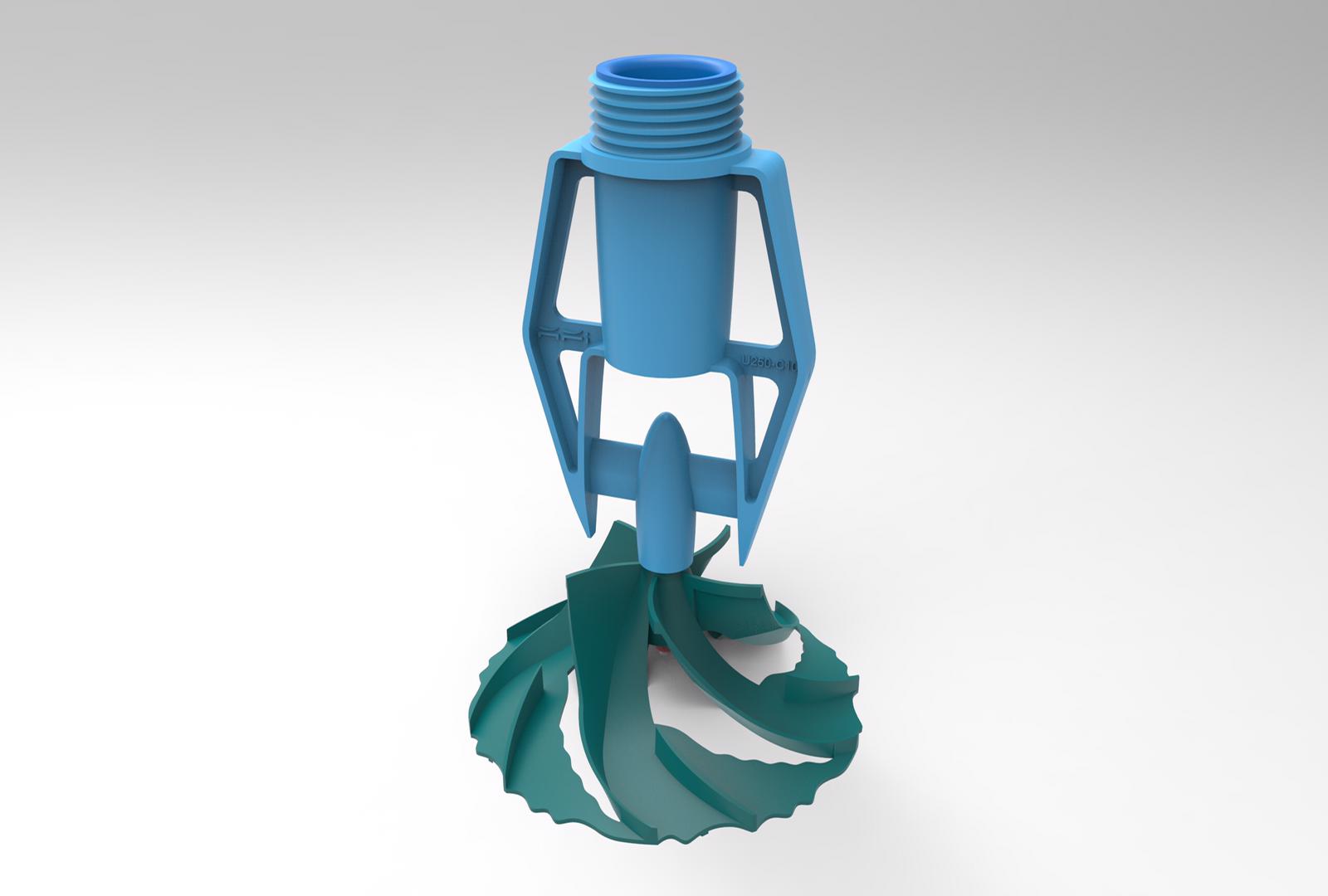

WATER DISTRIBUTION SYSTEM

It consists of a supply manifold in galvanized steel (or, on request, stainless steel / propylene), single or double according to the size of the tower, equipped with removable nylon static nozzle ranks. The diameter of the nozzles is generously sized to avoid any obstructions. The rank of nozzles ensures uniform distribution of the water to be cooled on the heat exchange pack.

DRIFT ELIMINATORS

They are mainly used to retain water droplets dragged vertically in the flow of humid air exiting the evaporative tower. Our technology has achieved exceptional goals in separation efficiency, making available two different designs SCAM / DRF-CL (CELLULAR line) and SCAM / DRF-SH (SHELL line) in PP / PVC.

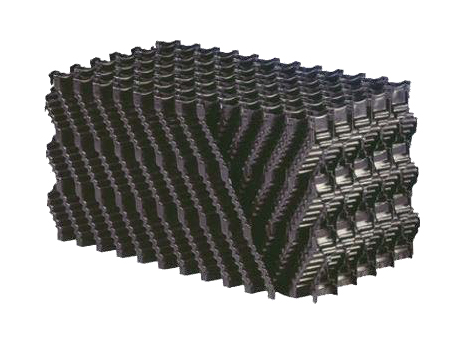

FILLING (OR HEAT EXCHANGE PACK)

It is placed inside the tower body, and provides the heat exchange surface necessary to guarantee the heat exchange between the flow of hot water, properly atomized by our nozzles and the flow of cold air coming from the outside going up against the process water. Filling is FILM type, narrow pitch, available in different materials (PP / PVC).

NOISE REDUCTION

Centrifugal towers suit very well environments that require a low acoustic impact, and in fact they can be silenced in different ways through sound-absorbing baffles placed in the air intake and expulsion. The position of the fans encapsulated in the lower part of the tower and keyed on a single motor shaft tends to reduce noise emissions. Furthermore, the collection basin is not directly exposed to the outside, and therefore the showering effect of water is not significant.