MAIN WET DIVISION PRODUCT

This “field erected” cooling towers series, is dedicated to every industrial sector whenever is needed an high water flow (heavy duty), these models are characterized by SCAM T.P.E. S.r.l. well defined standards and are supplied with a steel/stainless steel/GRP pultruded fiberglass structure to be assembled on site with dimensions that are compatible for road and sea transport.

The indirect transmission ventilation units, are designed for a long durability, with high quality components and with a very easy maintenance program.

The main feature that distinguishes closed circuit evaporative towers from open circuit ones is that primary fluid, which runs in inner tube beams, is totally separated from cooling fluid’s secondary circuit. Secondary circuit is made of a recirculating pump, which conveys water from basin to spray nozzles on the top side of the tower.

Tube beams water irroration allows the cooling of the inner fluid, using evaporative effect and consequential enthalpic exchange.

Recirculating fluid, which can be both in a liquid or a gaseous state, is never going on contact with ambience, avoiding any type of contamination.

VENTILATION UNIT

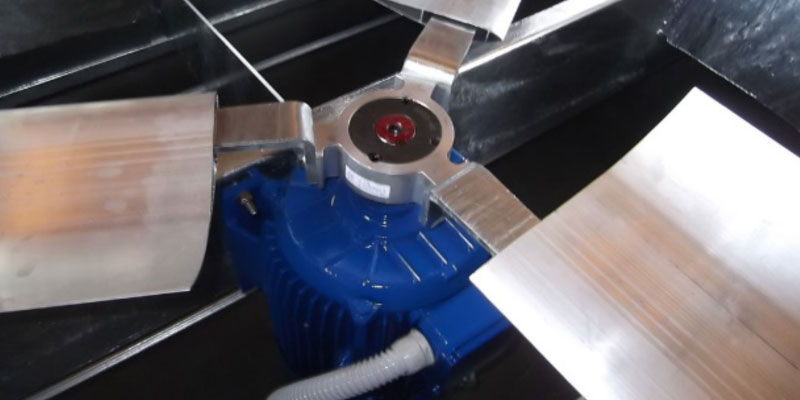

SCAM T.P.E towers are characterised by direct drive (fans are directly coupled to the electric engines) or, for FAS-FASF towers (more package modules with single fan), with speed reducer. The groups are characterised by the following features:

Electric Motors

The SCAM/SPMS specification modifies direct-drive electric engines. Although they are installed in humid environments, their reliability is ensured and maintenance is low.

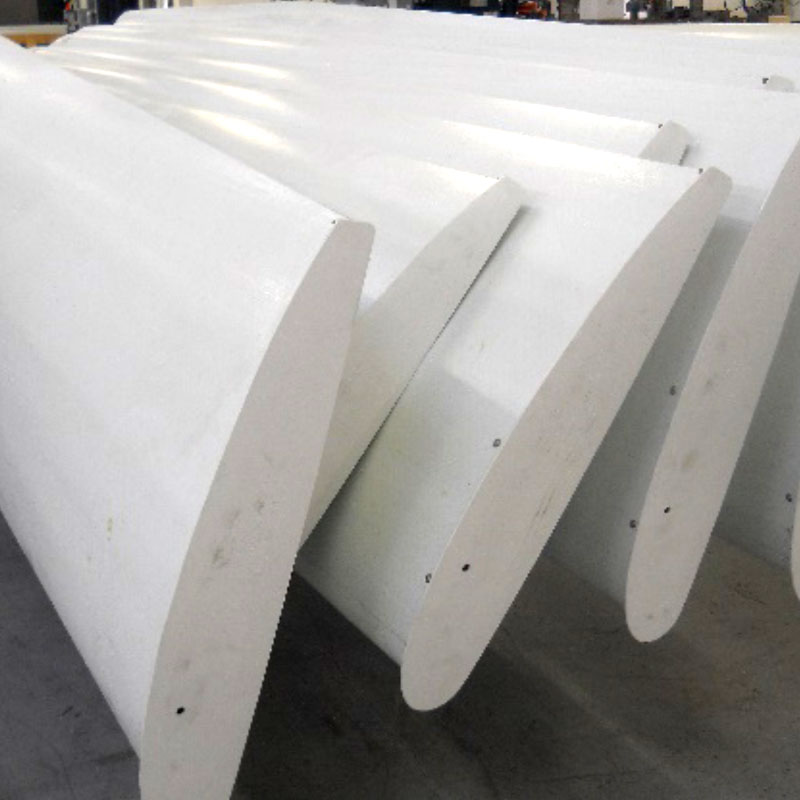

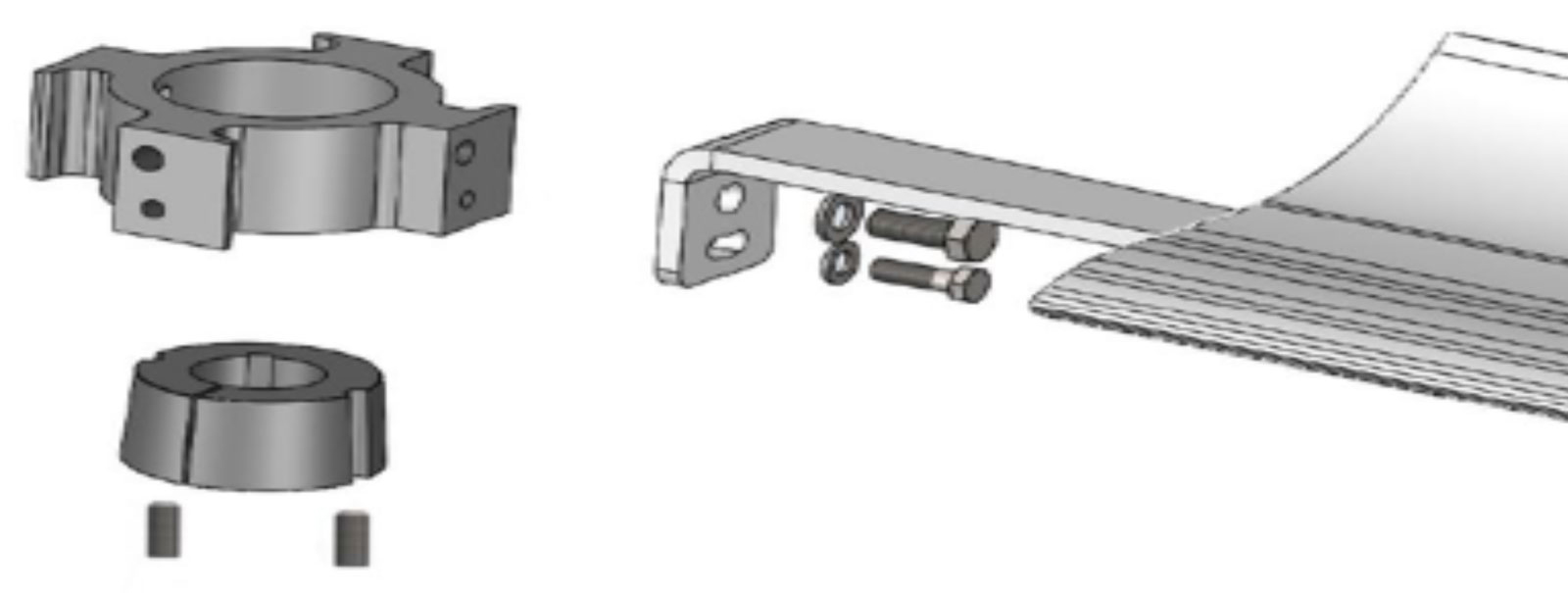

Fans

Induced suction is realised through multi-blade axial fans deriving from “NACA” aeronautics, with asymmetric profile. They are dynamically balanced thanks to the “master blade”, both in FRP and in light alloy. In case of specific acoustic propagation restrictions, a new kind of SCAMAIR/SX fan can be used, which is characterised by a profile shaped like an elephant’s ear.

Diffusers

They contain the dynamic components of the system. They are attached to the top of the tower. They have a truncated-pyramid profile that allows optimising energy consumption. They are provided with junction boxes where power cords are wired and connected as well as the switches for the detection of anomalous vibrations, with subsequent disconnection of the electric supply unit.

CARPENTRY - COVERINGS

They can be of two types:

1) Mullions and transoms of the tower body. They have a pre-assembled galvanised carbon steel structure in line with EN ISO 1461. Diffusers and collecting basin for cooled water. They are made of carbon steel sheet and, on pre-machined frame, they are protected with a thick hybrid treatment consisting of:

SCAMBOND/HYB CYCLE

• Sanding Sa2.5 ISO 8501-1.

• Epoxy cycle for internal surfaces.

• Epoxy galvanising cycle and polyurethane acrylic finishing for external surfaces. For this kind of structures, external covering consists of sandwich panels with variable thickness starting from 22mm, with expanded polymer core covered with a FRP external layer.

2) Monolithic structure of diffusers and collecting basin for cooled water in carbon steel sheet, which underwent continuous welding, with no synthetic junctions, shaped and with a ribbed structure with surface treatment, having the following features:

SCAMBOND/STD CYCLE

• Sanding Sa2.5 ISO 8501-1.

• Aliphatic polyurethane cycle for external surfaces.

• Polyamine epoxy cycle followed by epoxy bituminous cycle for internal surfaces.

All bolts for the above-mentioned cases are in stainless steel.

ELECTRICAL MOTORS TEFC

The electrical motors TEFC placed on our cooling towers, are designed on the basis of an experience gained in more than 50 years in the specific sector in the use on the open circuit cooling towers. Even if it is possible to use the indirect transmission by means of a speed reduction gear, SCAM T.P.E. prefers to use the “direct” transmission in the package cooling towers. This has the advantage to eliminate the trasmission organs, critical components that certainly raise the maintenance costs, forcing to many verifications and adjustments. In the case of direct transmission, the electric motors are placed in an atmosphere saturated with humidity and then exposed in a severe environment that is not without problems. To counteract possible breakages SCAM T.P.E. has developed a dedicated “SCAM / SPMS” specification, making its motors suitable for the application with an IP55 rating increased.

The interventions are part of the company know-how and make the engine component 100% reliable, here are the major interventions applied:

• Improvement of protection with tropicalization.

• Seal improvement.

• Sealing with special materials of some exposed parts.

• Replacement of bolts.

• Elimination of the terminal board.

• Best painting cycle.

• High quality 2RSC3 sealed bearings lubricated to life.

• Adoption of heaters anti condensation.

• At the discretion elimination of the cooling fan.

These examples of intervention, want only to point out some of the specialties developed in the time by SCAM T.P.E. technicians.

SCAMAIR AXIAL FANS NEW TECHNOLOGY

The multiblade axial fans of the “SCAMAIR” series that equip our evaporative towers, have the function of ensuring the necessary air volume induced by the high area of the tower. The impellers are engineered and built according to the experience gained in the field of evaporative towers since 1950, with blade profiles made of extruded aluminum 6060 T5 or plastic (PPG / PAG / fiberglass reinforced pultruded) according to the specific application.

All profiles are of “NACA” type of asymmetrical aeronautical derivation designed for maximum efficiency and durability with respect to the most severe acoustic standards. The blade hub has an unprecedented innovative design, engineered to reduce vibration to a minimum and allow one blade to be mounted at a time, for simplified and quick maintenance. The hub can be in galvanized steel or made from a single aluminum extrusion (incorrosible) and consequently worked with precision. The forces acting on the blades of the impellers are of alternate type due to the turbulences encountered during normal use: this type of inserts (supports inside the blades) and fixing systems allow it to oscillate slightly, allowing therefore the absorption of the vibrations generated.

The blades pitch is made possible when the impeller is on stop through simple registers allowing its inclination.

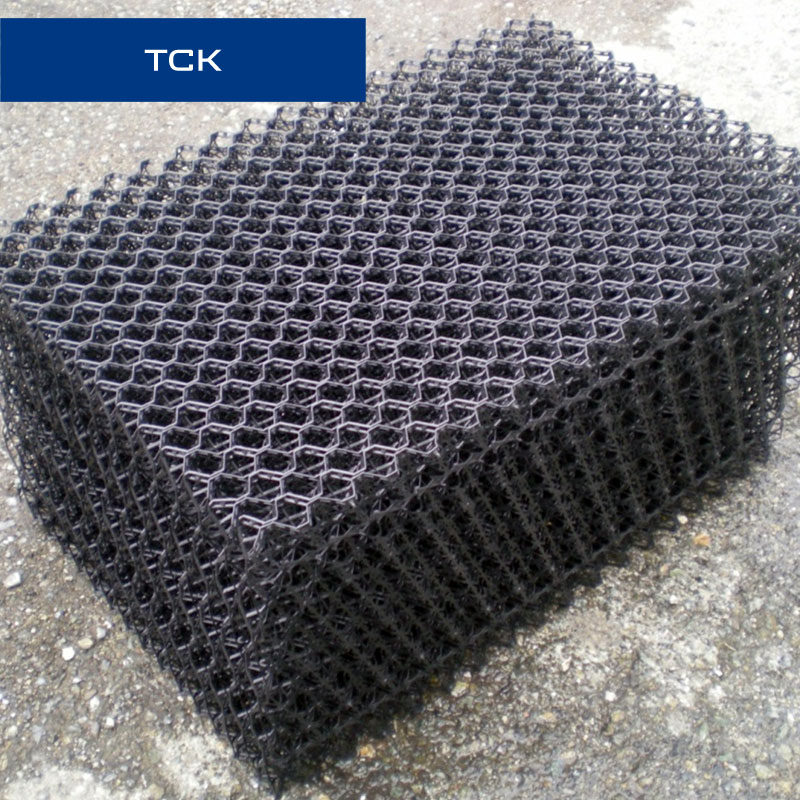

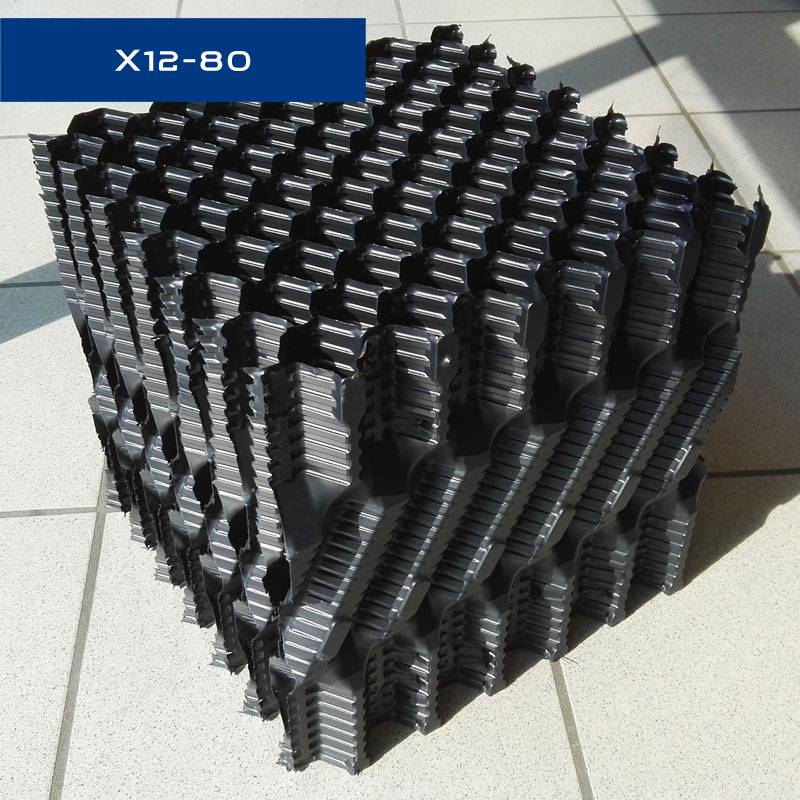

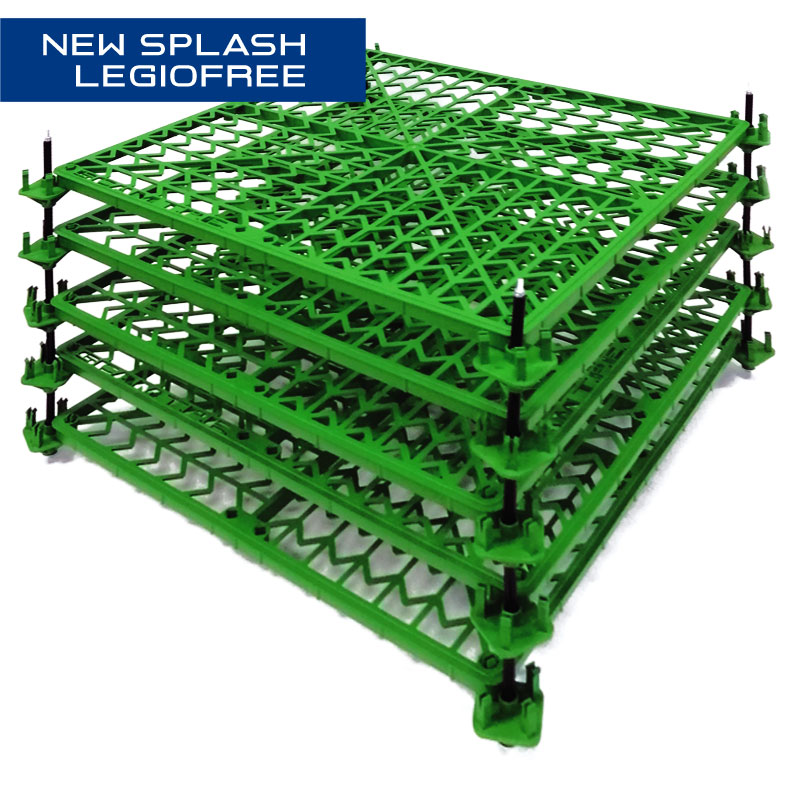

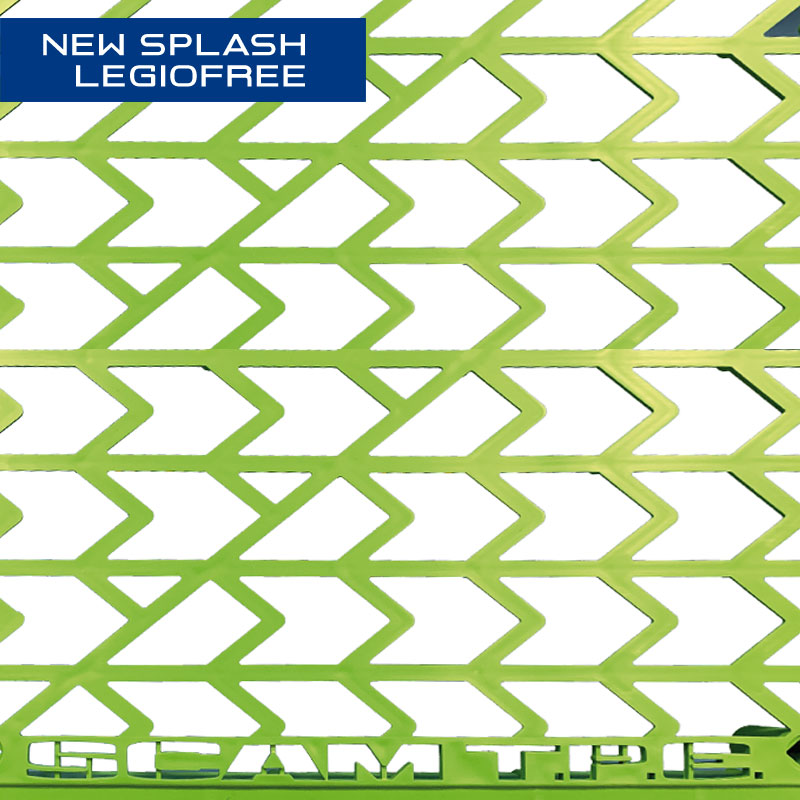

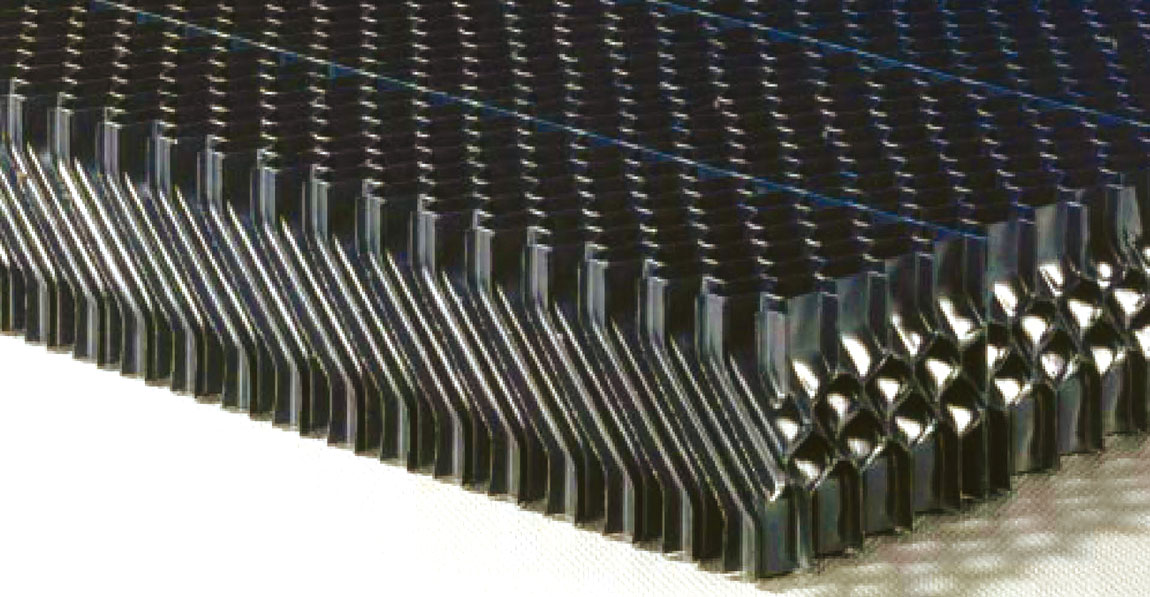

DISPERSION SYSTEMS

The two main families of dispersion systems, that is to say “Film” and “Splash”, are served by SCAM T.P.E. in line with the most advanced and constantly evolving standards. Over the years, this important characteristic system of refrigerating towers has been influenced by the use for clean waters (deriving from indirect exchanges such as heat exchangers, condensers and surface) or others, containing suspended solids (coming from barometric condensers).

The solids present in the air that clog the system, and more attention to both operating temperature and chemical aggressions, make it necessary to choose from a wider range of fillings that, after having been selected by a sophisticated calculation system, must be validated by long-standing experience. Multicellular film systems, splash with self-supporting grids, mixed, are usually selected by our software.

The continuous improvement of SCAM T.P.E S.r.l. refrigerating towers has led to the development of a SCAM/SHIELD internal plastic covering consisting from a barrier in GRP that covers the internal walls of the tower body, thus enveloping dispersion elements and ensuring several advantages, such as:

• Reduction of the “by-pass on wall” phenomenon of sprayed water with subsequent increased refrigerating capacity of the tower.

• Elimination of possible water leaks from the tower walls.

• Complete insulation of the hydraulic circuit. No contact with the structure in galvanised steel.

The last advantage mentioned, together with the possibility to use the SCAM/DURABONDHYB protective cycle for the basin (two layers of fibreglass to protect the metallic basin) make our towers comparable to the ones in fiberglass. However, we are thus able to have all the advantages of a solid and resistant steel structure.

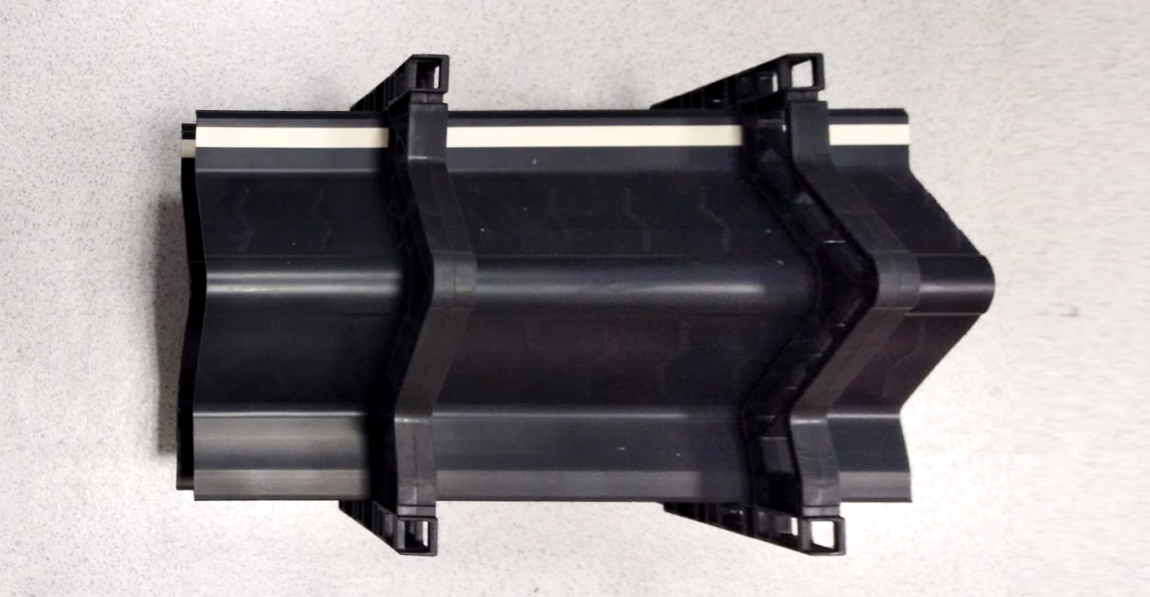

DROPS SEPARATORS

Located on the distribution system, they can be of different materials according to the operating temperature and to the fluids to be transported. Material range from PVC, PP, CPVS with multi-step processing to have less than 0.002% residues in circulating water.

WATER DISTRIBUTION SYSTEMS

Pressure system is used in that it allows a slightly variable “range” of capacity, thus being able to use highly efficient nozzles and preventing open systems from clogging.

The system consists of:

• Main pipe connected to secondary pipes realised in different materials and rationally sized in order to satisfy both a proper hydraulic charge and solidity in order to support the separators of drops.

• Highly-efficient dynamic nozzles, in propylene, assembled on the pipes by means of adaptors: this way, they can be disassembled for inspections and reassembled by means of threading.

A specific feature of these nozzles is their spraying capacity with “square” projection in order to eliminate dead spaces deriving from circular supply.