FAS / FASF series, FAS / FASF series, designed for maximum corrosion resistance, offers open circuit cooling towers, with a wide range of thermal potentials from hundreds of kW to very respectable sizes over 10 MW. All models apply a modular concept and are fully factory pre-assembled to minimize on-site installation costs. Fan groups are characterized by large dimensions and are assembled on site. Each model can be customized with dimensions and characteristics based on project needs and in order to respect environmental constraints with reduced acoustic and energy impact. Regarding this, special executions are provided for ATEX environments (“EX” versions), for low temperature environments (“SN” versions), for low noise emissions (“LN” version) and with energy optimization systems (“VDI version”).

This series is used in all sectors in civil and industrial field in presence of corrosive environments (for metallurgy and beyond) with excellent results, thus being able to avoid the use of expensive materials such as stainless steel for structures. The main features of these open circuit evaporative towers are the following:

STRUCTURE / MONOLITHIC ENCLOSURE (body, fan stack and collection basin).

The tower structure is characterized by profiles made of hot-dip galvanized steel in accordance with UNI EN ISO 1461: 1999. The panels on the sides are a “sandwich” 22 mm thick, with a core in polyurethane foam covered with fiberglass sheets (FRP fiberglass).

The fan stacks are usually in reinforced fiberglass with UV treatment composed in sectors to be flanged together with stainless steel bolts. Each diffuser has a circular and conical inlet fitting, the outlet section diverges to obtain a “venturi” effect on the air flow with a reduction in the power absorbed by the engine, improving the overall efficiency of the machines. Each fan stacks is equipped with an inspection panel to facilitate maintenance of the ventilation unit and is fixed to the tower structure by means of dedicated bolts that secure it to the galvanized steel walkway of the cooling tower.

The tower body, made of several pre-assembled modules placed one next to the other, can be fully inspected thanks to the inspection doors and removable FRP walls (for each cell), allowing the operator an easy entry.

An important feature for FASF towers is the presence of a particular coating called “SCAM / SHIELD”, consisting of a FRP sheet fixed with stainless steel bolts along the internal structural walls, wrapping the dispersion elements. In this way, the internal metal structure is completely isolated from the process water, and the phenomenon called “by-pass on wall” is also reduced. With the expression “by-pass on wall” we mean the water that, being nebulized on the internal walls of the tower, does not meet the air rising in against the current, (with consequent loss of efficiency). The perfect internal and external insulation therefore allows the meticulous elimination of any water leaks from the walls of the tower.

The collection basin, complete with all necessary connections for normal use, can be made on request in a weight-saving “self-draining” EU version in line with current European anti-legionella guidelines. The basin is supplied with a pre-assembled structure consisting of welded metal sheet panels protected with our hybrid protective cycle “SCAMBOND / HYB”, a high thickness hybrid treatment performed on carpentry consisting of a first layer of galvanizing on Sa3 sandblasted surfaces ISO8501-1, plus a specific bi-component epoxy-polyamine cycle, then applying a subsequent two-component aliphaticpolyurethane type. On the internal surfaces of the basin in the FASF series only, the diversified protective coating DURABOND / HYB is used: an evolution for aggressive environments consisting of a two-component epoxy-polyamide cycle preparatory to the subsequent FRP resin coating with the deposition of 2 hand-applied layers of glass fiber 450 g / m2 and a finish with epoxy / polyester resin (overall thickness 1500 g / m2).

BOLTS are supplied as standard on this model in STAINLESS STEEL or even DUPLEX on request.

Upon request, it is possible to propose stainless steel as the construction materials for the tower. With FAZ / FAX models (SS304 or 316 depending on the needs), where the characteristics of the project make it essential to use noble metallurgy, highly resistant to corrosion.

VENTILATION UNIT

In FAS / FASF series with small cell dimensions, a direct transmission for the ventilation unit can be provided. For this purpose, a SCAM T.P.E. electric motor is used, three-phase multivoltage (230/400 – 400/690) and multi-frequency (50-60 Hertz) specific for cooling towers, the result of the experience gained in this sector since 1936. In case of larger cells executions, an indirect transmission is provided, consisting of:

– High efficiency SCAMAIR / ST axial fan with asymmetrical “NACA” type profile of aeronautical derivation, designed for maximum efficiency and durability in compliance with the strictest acoustic standards. The components are of absolute quality such as the hub in galvanized steel or aluminium and the blades in FRP or aluminium alloy. All blades use the variable pitch solution with the fan stopped to optimize the tower performance and electricity consumption;

– Self-supporting transmission shaft able to withstand small misalignments that may occur in service; to absorb “shock”, vibrations and jolts. Joints are elastic type and reduce the time required for assembly and maintenance operations;

– Electric motor designed for severe conditions with continuous service type S1 IEC IE3 high efficiency as per new IEC 60034-30 standards. The motor is located outside the wet flow passing through the FRP diffuser and is self-ventilated. Supports of the electric motors are designed to transfer dynamic loads to the cooling tower structure, minimizing vibrations and allowing simple and intuitive maintenance;

– Gearbox with orthogonal axes with perfectly watertight stiffened casing and labyrinth seals;

– Abnormal vibration switch wired in an IP67 junction box located outside the ventilation conduct only to be plugged.

WATER DISTRIBUTION SYSTEM

In FAS series, distribution is made by means of pipes and fittings in hot-dip galvanized steel unified DIN or ASME with flanged connections, and composed by a main manifold with lateral branches equipped with “SCAM / NZ-RT” dynamic spray nozzles or “SCAM / NZ” static spray nozzles, both in PP.

In the FASF series, the water distribution pipes are made of PP (high density polypropylene) for a greater resistance against corrosion.

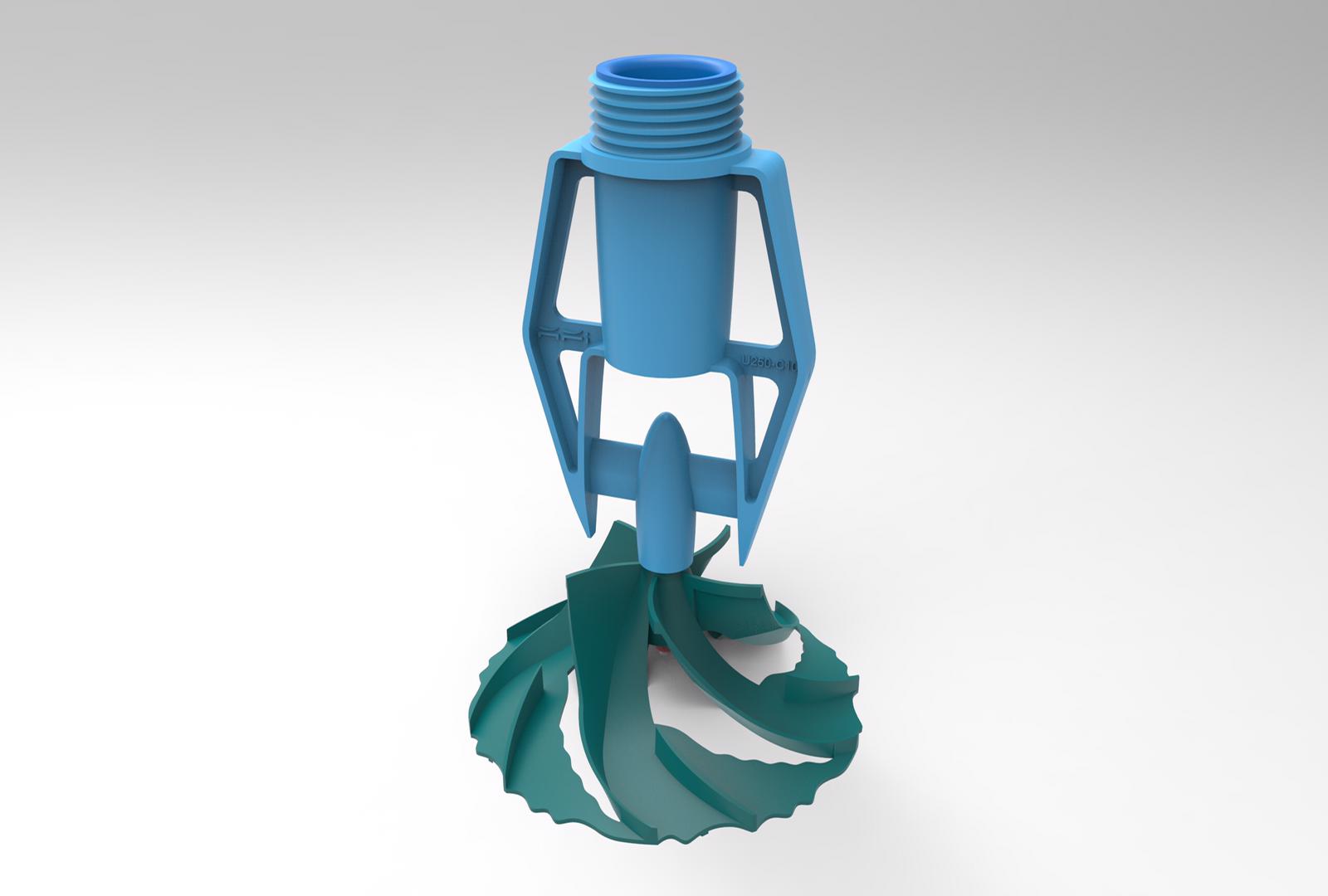

Our SCAM / NZ-RT rotating nozzles are highly efficient, work at low pressure, and allow for significant energy and economic savings. They are anti-clogging, equipped with interchangeable internal inserts, allowing them to be adapted in the event of variations in flow rate, if you were to work with a work pattern other than the design one

DRIFT ELIMINATORS

They are mainly used to retain water droplets dragged vertically in the flow of humid air exiting the evaporative tower. Our technology has achieved exceptional goals in separation efficiency, making available two different designs SCAM / DRF-CL (CELLULAR line) and SCAM / DRF-DW180 (in PP / PVC).

AIR INLET LOUVERS

They are placed in the intake air flow entering the cooling towers. They not only retain unwanted elements (such as foliage and debris), but also prevent water from splashing outside, which could cause ice formation during winter season. In addition, the windows are a barrier, limiting the sunlight entering the basin, thus hindering the growth of algae and microorganisms inside it. They are available in the SCAM / NET65 version in PP / PVC, customized in treated steel, or INOX / FRP, where the specifications require it.

FILLING (OR HEAT EXCHANGE PACK)

It is placed inside the tower body, and provides the heat exchange surface necessary to guarantee the heat exchange between the flow of hot water, properly atomized by our nozzles and the flow of cold air coming from the outside going up against the process water. Depending on the quality of circulating water, and therefore depending on the suspended solids present in the cooling circuit, the filling is available in different PP / PVC materials and FILM, HYBRID and SPLASH systems.

SPECIAL VERSIONS

In addition to the standard materials (Polyvinyl chloride PVC or Polypropylene PP), the plastic parts inside the tower can be supplied in special materials (CPVC overchlorated,

PVC HT for high temperatures, ABSPVC with excellent non-flammability qualities, PPS …) for particular operating conditions at customer specification.